RPET refers to the use of waste polyester bottle flakes, spinning waste, foam material, pulp blocks as raw materials, usually mineral water plastic bottles or cola bottles, the bottles are cut into small pieces, crushed, and the flakes are melted to separate the core PET components, recycled granulation, spinning into fibers and weaving, which can be used to make anything.

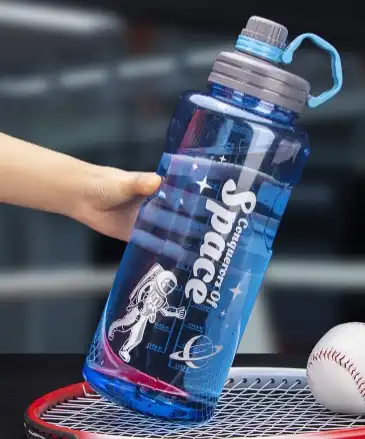

FuWinn has RPET material certificates and can also produce REPT plastic water bottles. Please contact us if necessary.

What are the production processes of recycled polyester RPET?

After recycling, crushing, washing, drying, melt extrusion, spinning, winding, bundling, drawing, curling (at the same time, different oils are added during curling according to customer needs), relaxation and heat setting, and cutting to form polyester fibers of different lengths, polyester is a synthetic material.

It is mainly an environmentally friendly material extracted from waste recycled PET plastic bottles using physical or chemical technology. RPET is mainly used in industry, clothing, home textiles, and luggage materials, such as mountaineering bags, shopping bags, down (cold-proof) clothing, sportswear, umbrellas, tents, etc.

How to distinguish PET from other materials?

PET plastic bottles are made of polyethylene terephthalate, commonly known as PET. Whenever we pick up recyclables, we always take PET bottles as the main material and other recyclables as the auxiliary, because the price of PET bottles is the best when they are recycled, but its material is easily confused with PVC material.

Its characteristics are as follows: PET is transparent, tough, and has a barrier to carbon dioxide. It is often used in the packaging of carbonated beverages. The simplest way to identify it is that it is colorless and transparent. After adding color, it can become light green, light blue or brown. There is a dot on the bottom of the round PET bottle, and the bottle body has no seams.

The bottom of the PVC round bottle is a straight line. There will be white marks when it is bent. It will turn iron red after long-term exposure to sunlight. When burning its edge with fire, there will be a blue flame, and the burning property is poor.

PET bottles are widely used in carbonated beverages such as Coca-Cola, Pepsi, and Sprite. Currently, most of them are composed of PET bottle body and HDPE bottle bottom. The bottle cap material is HDPE, and the trademark is biaxially oriented polypropylene (BOPP) film, which is adhered to the bottle body with EVA adhesive. The recycling of polyester bottles can be reused by regeneration granulation, alcoholysis and other methods.

How to extract RPET?

Regardless of the method used, the polyester plastic bottle must first be separated from other bottles, and the polyester bottle body must also be separated from the bottle bottom. The specific operation methods are as follows.

① Separation

The mixed collected bottles are crushed in a crusher through a conveyor belt and then separated by density.

② Regeneration granulation

Regeneration granulation can be done with an extruder. The separated PET crushed materials are extruded and granulated into granules by an extruder. In order to avoid water absorption during extrusion and reduce the physical viscosity, they should be dried before extrusion.

③ Alcoholysis

PET waste is subjected to alcoholysis in the presence of an alkaline catalyst, and then dibasic acid anhydride is added for polycondensation to obtain a product with an acid value greater than 12. After dilution, filtration, and addition of an appropriate amount of catalyst, an alkyd resin paint can be obtained. The reaction temperature is 80~85 degrees and the reaction time is 4~5 hours.

What about RPET uses?

When you said RPET, you may think of only for plastic bottle. Not correct. It can be used in many area.

a. Re-manufacturing PET bottles.

Recycled pellets cannot be used in direct contact with food, but can be used in the middle layer of three-layer PET bottles and then made into carbonated beverage bottles.

b. Spinning to make fibers.

Recycled PET materials can be used to spin fibers for pillow cores, mattresses, sleeping bags, felts, etc.

c. Glass fiber reinforced materials.

Recycled PET reinforced with glass fiber has good heat resistance and mechanical strength. It can be used to make automotive parts, such as heat-resistant automotive wheel covers. Its thermal distortion temperature can reach 240 degrees. Flexural elastic modulus 9500MPa, bending strength 214MPa, impact strength 15kf/m2.

d. Blending modification.

Recycled PET polyester non-woven fabric can be blended with other polymers to make various modified materials. For example, blending with PE can obtain PET blends with improved impact performance. PE:PET is (10-50): (90-50): If a small amount of polypropylene is added, the dimensional stability of the blend can be significantly improved. Since the polarity of PE and PET is quite different, compatibility treatment is required during blending. Generally, the compatibility is improved by grafting modification of polyolefins.

What are the relevant applications of RPET in the industry?

After reading the above, I believe everyone has a preliminary understanding of RPET. Since the market consumption of this recycled material is so huge, are you curious about what fields these are applied to? Let’s take a look. RPET can be widely used in industry, clothing, home textiles and other categories.

(i) Industrial category

It includes mountaineering bags, shoulder bags, school bags, pencil cases, children’s backpacks, travel cases, shopping bags, handbags, gift bags, plastic cups and drawstring bags, etc.

(ii) Clothing category

It includes down (cold-proof) clothing, windbreakers, jackets, anti-static work clothes, fashion, pajamas and sportswear, etc.

(iii) Home textile category

It includes bedding sets, blankets, toys, car cushions, sofa fabrics, curtains, pillows, backrests and baby strollers, etc.

(iv) Other categories

It includes tents, sleeping bags, hat materials, shoe materials, car accessories, etc.

Do you know the manufacturing process of RPET yarn?

Plastic bottle recycling → Plastic bottle inspection and separation → Plastic bottle slicing → Drawing, cooling and collecting → Recycle Fabric (recycled synthetic fiber) yarn → woven into fabrics.

Now Coca-Cola has announced the launch of 100% rPET 500ml soft drinks in the Hong Kong Special Administrative Region. In this new initiative, all 500ml Coca-Cola Original, Coca-Cola Sugar Free and Coca-Cola Plus will transition to 100% rPET bottles, excluding caps and labels. As the first 100% rPET Coca-Cola branded product packaging in Hong Kong, the packaging is printed with the message “I am a 100% rPET bottle” and “Recycle me” to raise awareness of recycling and encourage consumers to take action.

Since 2018, the RPET recycling market has shown an explosive trend. There are two main driving forces: on the one hand, global laws have stricter requirements for plastic packaging and set higher recycling rate standards. On the other hand, international brand companies have created a broad market for PET recycled materials. FuWinn has had insight into environmental protection for a long time, so we can meet the needs of customers and have various environmental certificates, such as GRG, RCS, RPET, etc.