We, FuWinn Housewares, have strict quality requirements. Regardless of whether the customer has inspection requirements for the travel mugs, we will control our quality according to the requirements of the third party. Because we want to be the eyes of our customers in China, it is our responsibility to ensure good quality.

So how do we implement these quality methods for the travel mugs?

FuWinn Housewares will control it from many aspects for travel mugs, such as personnel experience, inspection AQL standards, equipment and tools, and delivery status.

1. What requirements do we have for inspectors?

First of all, the inspector must have sufficient experience in the relevant field. Before receiving the task, familiarize yourself with the order-related information in advance. When inspecting goods on the same day, you must arrive at the designated place before 9:30 a.m. And the working time cannot be less than 5 hours. If there are special circumstances, you must promptly explain to the company and obtain the company’s consent.

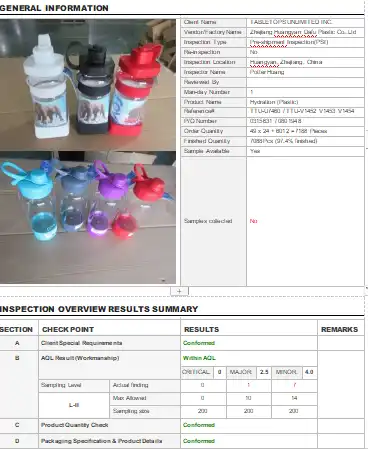

2. How to operate the AQL standard?

Our inspection personnel will randomly select boxes based on the total number of boxes and draw a root number. If there are multiple products in a report, the number of boxes must be extracted based on the total number of boxes of each product.

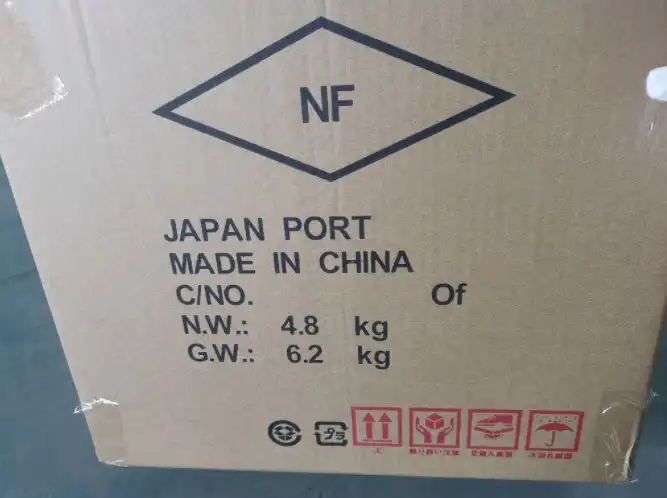

When taking photos, pay attention to focus and make the picture clear. And use arrow paper to indicate where the Defects problem is. And the following photos must be clear like, outer carton mark, number of cardboard pits in the carton, inner carton packaging method, individual product sales packaging, stickers/cloth labels, product details (logo, label, style…), etc. ..

Our personnel must be strictly inspected and all problems must be truthfully reflected in the report.

3. Equipment tools

When inspecting the instruments and equipment used, you must check the calibration status of the instruments and equipment, and take pictures of the calibration information and put it in the report. If it is not calibrated, please make a clear note in the report.

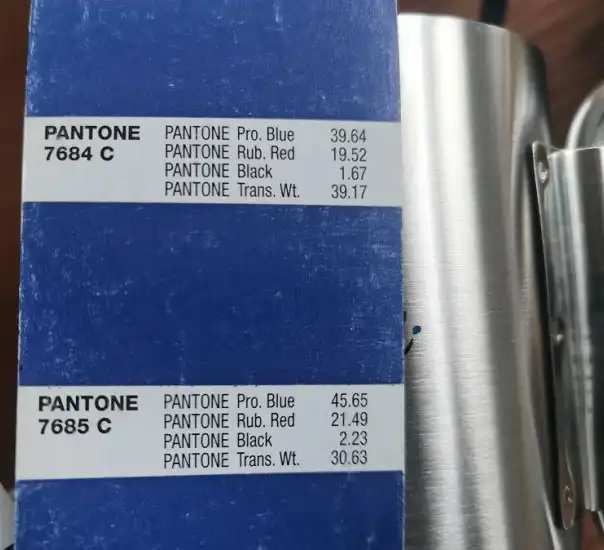

The inspector will bring all the tools for inspection, such as: laptop computer, digital camera, tape measure/caliper, barcode scan, arrow paper, hygrometer, color card, etc.

Apart from the above, do we have anything else special?

Yes. Because our customer contact personnel and quality personnel are separated, in order to complete the work more efficiently, when our inspectors go to the designated place, they will hold a PP pre-production meeting with our office merchandisers there. Make sure that the content of each point and the content of the information are all correct, and the information is not transmitted incorrectly.

Of course, during the pre-delivery meeting, we also need to check the opening time of our order staff on site together.

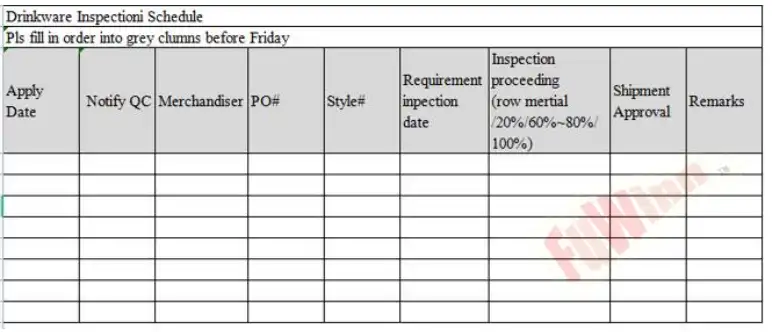

How do we internally connect data with the inspectors?

We will have relevant colleagues send all inspection plans for next week to our inspection personnel before Thursday or Friday morning. When receiving the information, the inspector will check it with relevant colleagues. Ensure information consistency to avoid unnecessary losses and trouble caused by discrepancies. We have an internal docking table below for reference.

Will we only do final inspection?

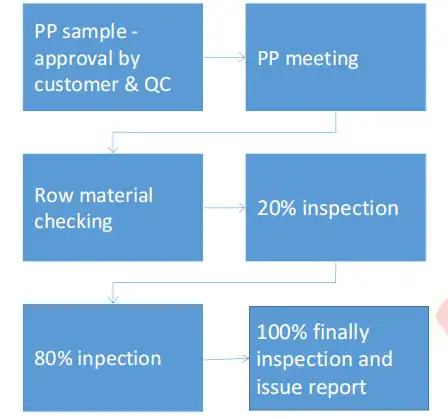

Of course not. We have multi-step and multi-time inspections. As you can see from the table above, we have at least 3 inspection steps before shipping.

Because we have seen too many examples around us, it is often not until the last step of shipping that the problem is discovered, and then we rework and push the delivery date to the buyer. This will force the buyer to change the original sales plan.

So in order to avoid such problems as much as possible, we start from the raw materials and confirm them before small batches are released, including in the mid-term. In reality, we inspectors know more than this fact. When they find a little problem, they will not leave until it is corrected. Protect our quality.

All in all, our inspection process is roughly as follows.

The following is part of our inspection report for travel mugs. Each report is the hard work and hard work of our inspection personnel.